Forge Nano Transforms Advanced Semiconductor Chip Manufacturing with High-Speed 1000:1 Aspect Ratio Atomic Layer Deposition Coatings

Breakthrough turbulent flow technology eliminates semiconductor manufacturing's most stubborn bottleneck, enabling high-speed production of next-generation AI chips and 3D architectures

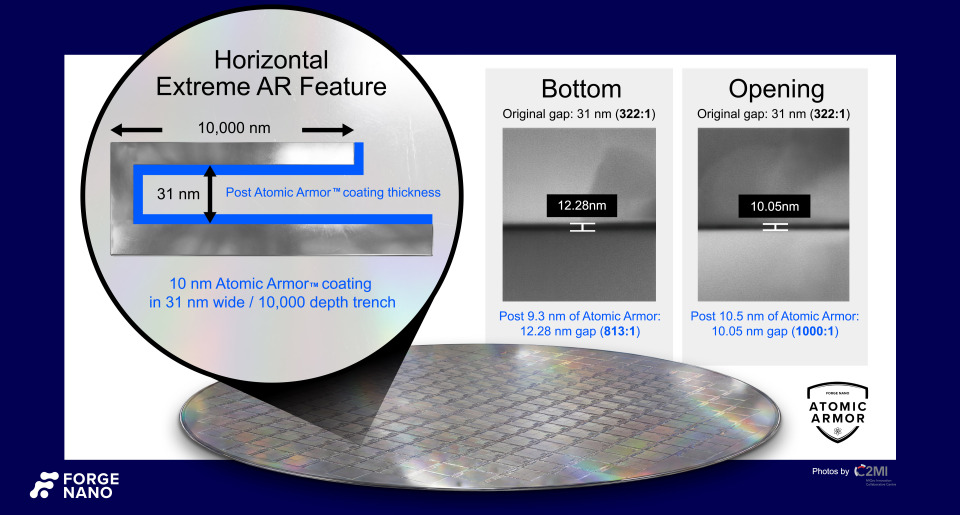

DENVER, Feb. 05, 2026 (GLOBE NEWSWIRE) -- Forge Nano, Inc., a technology company pioneering domestic battery and semiconductor innovations, today announced a breakthrough that fundamentally redefines the economics and architecture of advanced semiconductor manufacturing. The company has demonstrated high-speed, defect-free atomic layer deposition (ALD) coatings in semiconductor features at a 1000:1 aspect ratio. Conformality is maintained at production-scale while providing coverage on features 2 orders of magnitude greater than line-of-sight techniques.

This breakthrough removes the primary constraint that has limited 3D semiconductor scaling and enables architectures previously considered uneconomic or impossible.

The demonstration was performed on production-representative wafers supplied by C2MI, a leading semiconductor process development and manufacturing innovation center in Canada, with conformality, defectivity and electrical performance independently validated through the partner's internal metrology and reliability testing.

Revolutionary Technology, Revolutionary Results

While the ALD industry typically relies on laminar flow processes, Forge Nano has developed a patented turbulent flow approach that unlocks performance previously unachievable in high-speed ALD. Leveraging its Atomic Armor™ coating platform technology and next-generation TEPHRA™ production tools, Forge Nano achieved conformal ALD coatings in extreme nanoscale features – a regime where conventional deposition techniques fail and other ALD tools struggle with throughput. Forge Nano’s Atomic Armor ALD coating process has also been demonstrated at 10x the speed of competitive coating abilities for high aspect ratio coatings – the industry’s most throughput- and cost-limiting processes.

"AI chips and 3D-stacked devices expose the industry's weakest links – interfaces, defects, and contamination," said Paul Lichty, CEO of Forge Nano. "By achieving what the industry considered impossible – high-speed, conformal ALD at 1000:1 aspect ratio with production-scale throughput – we've fundamentally eliminated the primary bottleneck constraining the next-generation of semiconductor architectures. Only turbulent flow can unlock the ultra-high aspect ratios critical to 3D architectures. We're not just improving the process – we're changing the entire equation for how advanced semiconductors can be manufactured."

Breaking the Constraint That Shaped a Decade of Chip Design

At today's leading-edge semiconductor nodes, ALD is already one of the slowest, highest-cost steps in the fab. These productivity losses are tolerated only because there is no viable alternative.

Forge Nano's breakthrough changes that equation completely by simultaneously delivering 1000:1 aspect ratio conformality, ALD-quality film uniformity and speed. This is one of the rare semiconductor innovations that can improve yield, throughput and cost simultaneously.

3D NAND Memory: A New Roadmap

Current production NAND devices feature 200–300 layers. Moving beyond this has required increasingly complex processes and sharply rising costs. Maintaining high throughput for increased aspect ratio fabrication will enable higher density 3D NAND flash memory for advanced compute applications.

DRAM and HBM: Breaking the Capacitor Wall

For DRAM and high-bandwidth memory (HBM) critical to AI accelerators, capacitor scaling is the limiting factor. Fast 1000:1 ALD enables deeper capacitors with thinner, more uniform dielectrics – extending DRAM scaling past nodes many experts expected to be the "capacitor wall."

Material Improvement in Fab Economics

ALD today is one of the highest cost-per-wafer steps in semiconductor manufacturing, frequently constraining fab output and forcing duplicate tool purchases purely for capacity.

A fast 1000:1 AR ALD process can deliver:

- Increased wafer starts per day

- Reduced capex per node

- Improved energy and precursor efficiency

- Lower cost per bit (memory)

- Elimination of the ALD bottleneck that currently throttles node transitions

Industry-Changing Implications

This breakthrough represents a platform-level shift in semiconductor manufacturing:

- Architectural freedom: Enables designs previously considered uneconomic or impossible

- Competitive dynamics: Shifts power toward manufacturers who adopt this technology first

- Strategic significance: Creates national-security-relevant capabilities in advanced semiconductor production

- Market positioning: Establishes a new category leader in the most critical deposition technology for next-generation chips

By combining extreme aspect-ratio conformality with production-scale throughput, Forge Nano is redefining what's possible in advanced chip design and positioning Atomic Armor ALD as a foundational technology for the future of AI and 3D-integrated devices.

About Forge Nano

Forge Nano is a technology company pioneering domestic battery and semiconductor innovations using its platform technology, Atomic Armor™. Atomic Armor™ is a scalable, adaptable nano-scale coating system that strengthens America’s most critical systems – at the atomic level. The superior surface coatings produced by our Atomic Armor™ process allow our partners to unlock peak performance. Learn more at https://www.forgenano.com.

Media Contact

Will McKenna

Brand Communications Director, Forge Nano

wmckenna@forgenano.com

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/5273ac18-b480-42b8-a36a-6971a9ef50d3

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.